|

Parker Rectus ¿˚þ_ïrπ´ÀæÐâµ¿ΩªÕ®��°¢þ\ðîÐáðvë™”√øÏÀŸΩ”Ó^

Rectus Transportation ®C Railway Quick Connect Coupling Systems for Rail Vehicle Applications

We meet the highest requirements!

Quick connect coupling systems from Parker ®C a safe solution

in the area of rail vehicles

ÅÌ◊‘√¿á¯≈…øÀParkerπ´À浃Ðâµ¿ΩªÕ®þ\ðîÐáðvπЬ∑∞≤»´øÏÀŸþBΩ”Æa∆∑Ω‚õQ∑Ω∞∏

’ÒÑ”�����°¢ª“âm∫ÕòO∂ÀµƒôC–µ∫Õö‚∫Úâ∫¡¶ «Œ“ÇÉ‘⁄Î䡶∫Õ≤Ò”ÕÑ”¡¶Ð⵿ÐáðvÓI”ÚµƒøÏÀŸþBΩ”œµΩy√Ê≈Rµƒ÷˜“™ÃÙë���£¨œµΩyµƒ∞≤»´π¶ƒÐ∆÷¯÷˜“™◊˜”√���°£þ@¿Ô”–‘S∂ýÎä◊”�����°¢ö‚Ñ”∫Õ“∫â∫øÿ÷∆����£¨≥˝¡Àø…øø–‘£®π ’œ∞≤»´£©∫Õø…”√–‘∑Ω√ʵƒ“™«Û�����°£ÃÿÑe «‘⁄Ö^”ÚËF¬∑��£¨”–æþÛwµƒ÷∏¡Ó∫Õ∞≤»´òÀú µƒþ^≥㨌“ÇɵƒœµΩy±ÿÌö◊Ò ÿ£®¿˝»Á’ÒÑ”∫Õõ_ìÙúy‘á∞¥’’DIN EN 61373 / IEC 61373£©��°£

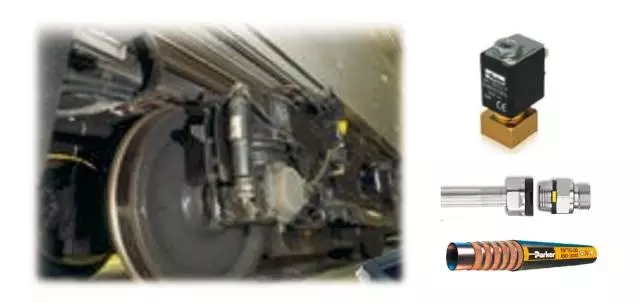

Vibrations, dirt and extreme mechanical and climatic stress are the principal challenges for our quick connect coupling systems in the area of electric and diesel-powered rail vehicles.The functional safety of the systems plays a major role

here with the many electronic,pneumatic and hydraulic controls, in addition to the requirements with respect to reliability (failure safety) and availability. Particularly in the area rail, there are specific directives and safety standards

for processes, with which our systems must comply (for example the vibration and shock test in accordance with DIN EN 61373/IEC 61373).

Quick connect coupling systems from Parker ®C a safe solution

in the area of rail vehicles

Parker Hannifin quick connect coupling systems for rail

vehicle applications

PDF Free DownloadŸY¡œœ¬ðd

With over 60 years of experience in the development and sale of high-quality quick connect coupling systems, the Quick

Coupling Division Europe of Parker Hannifin ®C the world°Øs leading manufacturer in motion and control technologies ®C now offers one of the most extensive product ranges of innovative connection solutions. Whether for complete or sub-systems, we

always have a tried and tested solution.

From standard product to bespoke systems, our team is available to provide you with competent advice at any time. We are happy to provide detailed advice ®C please ask us.

ÐÎäπ≠œµΩy£∫

- ö‚∏◊

- ƒ£âKªØøÿ÷∆œµΩy

- æ´√Ðö‚Ñ”úpâ∫Èy |

Ò{ÒÇ “ÐáÈTøÿ÷∆

- ÐáÈTàÖ–‘™º˛

- øÿ÷∆Èy

- ∞¥‚oøÿ÷∆

|

ÐáÛwÉA–±œµΩy

- ƒ£âKªØøÿ÷∆◊”œµΩy

- ë“íÏœµΩy

- Îä◊”úpâ∫Èy

|

Õ‚ÈTøÿ÷∆

- ÐáÈTàÖ–‘™º˛/ÈTÊi

- øÿ÷∆Èy∫Õƒ£âK Ωøÿ÷∆œµΩy

- æoº±þM/≥ˆ‘Olj

- ∞¥‚o

- ’œµKôzúy

- EOø®Ã◊ Ω‰ìπÐΩ”Ó^

- Ðõπк∞øÇ≥…

- øÏìQΩ”Ó^

- øÏ≤ÂΩ”Ó^º∞ü·ÀÐπÐ

- ≤ª‰P‰ìπÐ

- πÐäAº∞ÈyÓê |

ÞDœÚºÐœµΩy

- EOø®Ã◊ Ω‰ìπÐΩ”Ó^

- øÏìQΩ”Ó^

- Ðõπк∞øÇ≥…

- ≤ª‰P‰ìπÐ

- πÐäAº∞ÈyÓê |

÷∆Ñ”œµΩy

- EOø®Ã◊ Ω‰ìπÐΩ”Ó^

- øÏìQΩ”Ó^

- Ðõπк∞øÇ≥…

- ≤ª‰P‰ìπÐ

- πÐäAº∞ÈyÓê

- ƒ£âKªØøÿ÷∆œµΩy

- ∑¿ÊiÀ¿øÿ÷∆œµΩy

- ÷∆Ñ”◊˜”√Èy

- ∏ÙîýÈy

|

≥ÀøÕç≤Ωøÿ÷∆

- ö‚∏◊

- ö‚Ñ”àÖ–∆˜

- øÿ÷∆Èy |

Ðá„^œµΩy

- EOø®Ã◊ Ω‰ìπÐΩ”Ó^

- Ðõº∞øÇ≥… |

–‘ƒÐÃÿ¸c

- High resistance to vibrations and dirt (e.g. NSR-Series).

- Certified safety ®C vibration and shock test in accordance with DIN EN 61373/IEC 61373.

- Low pressure drop for maximum energy efficiency.

- Compact design for installation in applications where little space is available.

- Various sizes from nominal diameter 3 mm up to 50 mm.

- Broad selection of sealing materials for optimal co-ordination with temperature (-55°„C up to +250°„C)

and flow medium.

- High resistance to rotation.

- No leakage when disconnected due to the specially developed valve design ®C even after a long time and

pressurisation (all flat-sealing variants).

- Push-pull function ®C pull-off function for system safety and time saving, particularly with systems in motion (e.g. FF-Series).

60 Years of Know-How

We set standards industrywide

|

|

≤ƒŸ|Materials

For coupling systems in the area of rail vehicles,

the materials brass, stainless steel and aluminium

in particular have proven themselves. Brass

is generally used with a nickel plated finish ®C

depending on the series, we offer stainless steel in

qualities AISI 303, AISI 316 L and AISI 2205. Other

materials are also possible of course, depending on

application. Our team is happy to advise you here |

√Ð∑‚Seals

A coupling can only be as good as its sealing

components. This is why we rely on EPDM and

NBR as standard for our sealing materials ®C

particularly NBR for extremely low temperatures.

For challenging requirements, our experts will,

of course, offer completely individual advice and

develop an optimum solution. |

|

|

ÈyValves

Depending on the application area, Parker

QCDE coupling systems are available with

straight-through, single or double shut-off,

and in clean break design. To ensure fault free

operation all valve seals are the same as the

main seal choice. |

ª“âm∑¿◊o—b÷√Dirt Protection

For outdoor applications, we have developed

coupling systems that have seals integrated both

into the unlocking sleeve and into the plug ®C the

complete coupling (incl. locking system) is therefore

sealed when coupled and it is effectively

protected from dirt and spray water. |

Your Reliable Partner

We develop complex quick connect coupling systems for rail

vehicle applications

The comprehensive range of critical components from Parker QCDE combined with our ability to develop and produce complex, integrated systems for almost any application makes us a strong partner to planners,manufacturers and suppliers in the area of rail vehicles.

From the concept and launch of products to production that is sustainable in the long term,we offer intelligent solutions in the area of cooling, braking and battery systems and plumbing,and in many pneumatic and hydraulic applications.A brief insight into our range of services is provided below.

ø’’{∫ÕÎä◊”¿‰ÖsœµΩy

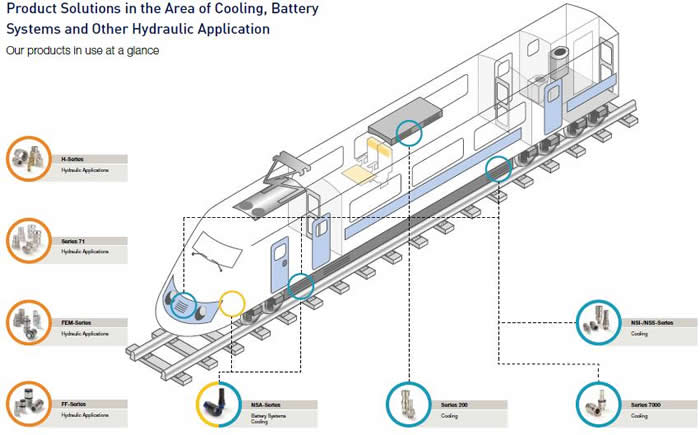

Air Conditioning Systems and Electronic Cooling

Quick connect couplings from Parker QCDE for cooling systems are a reliable and powerful

solution. They guarantee optimal cooling of many applications used in diesel-powered or

electric rail vehicles.

- Quick connect couplings in the area of air conditioning systems.

- Dissipation of heat arising from electrical power loss.

- We provide efficient cooling quick couplers for transformers, converters, traction motors

and virtually all areas of cooling for electronic applications.

ö‚Ñ”ÑxÐ᜵Ωy

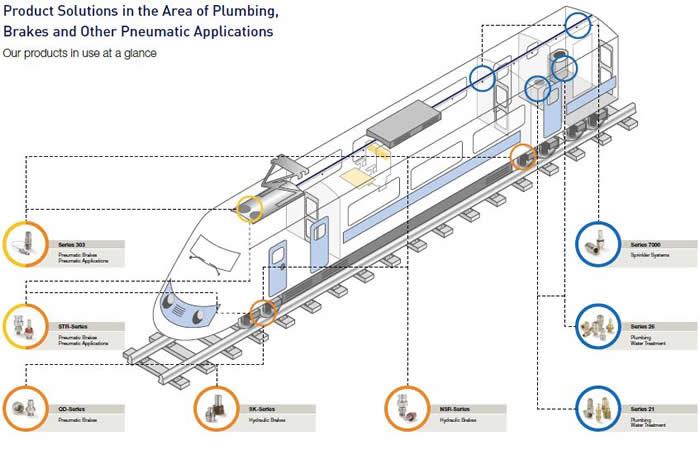

Pneumatic Braking Systems

Our range includes special coupling systems for functional testing of braking systems. These

systems are used both in the initial fitting and in continuous regulation braking tests before any

use of a rail vehicle.

- Reliable and rapid functional testing with easy handling.

- Maximum compressed air efficiency from functional couplings with blanking plugs.

- Special test couplings control the various braking circuits individually.

- Measurements of the braking signals directly on the rim mounting.

- Developed for temperatures down to -55°„C.

“∫â∫ÑxÐ᜵Ωy

Hydraulic Braking Systems

Coupling systems from Parker QCDE stand out for their process reliability even under extreme

conditions. This makes them the ideal solution for hydraulic braking systems.

- Quick connect couplings link the wagon and bogie hydraulic braking circuits and thus

allow a direct, dynamic system.

- Environmentally friendly and easy-clean solution due to the flat-sealing locking system. In

the coupling process, the inclusion of air/dirt in the circuit is avoided.

- Special dirt protection protects the unlocking mechanism of the sleeve and guarantees the

function of the coupling/unlocking process.

é˙À˘œµΩy����£¨ÀÆÃé¿Ì∫Õ◊‘Ñ”áäÀÆúÁªœµΩy

Toilet Systems, Water Treatment and Sprinkler Systems

Quick connect couplings are also used in the area of on-board toilet systems and water treatment

in mobile installations. A special system has been developed in the area of vacuum

toilets.

- Development of a complete system: series 26 is jointly responsible for filling the water

tank; series 21 brings applies pressure to the toilet in the flushing process so that the

water can be flushed out accordingly ®C until the purge valve is opened.

- Use of non-corroding coupling systems.

ö‚є뙔√

Pneumatic Applications

To this day, pneumatics remains an important element in rail vehicles. Coupling systems

from Parker QCDE are used in many applications for connecting compressed air components:

- In purely pneumatic door drives.

- For folding steps, sliding steps and ramps with pneumatic drives.

- In sanding systems.

- In pneumatic pantograph systems.

“∫â∫ë™”√

Hydraulic Applications

Hydraulic couplings are essential for coupling and uncoupling attachments on rail and track

vehicles. From railway construction machines to winter and summer equipment (e.g. snow

plough, snow blower, mulcher etc.), almost all equipment can therefore be changed quickly

and easily.

- Flat-face systems guarantee protection of the environment and of the hydraulic circuit.

- Quick and easy assembly.

- No freezing of the unlocking sleeve in winter.

- Pressure eliminator allows coupling even with residual or dynamic pressure. The special

valve structure automatically relieves the pressure in the coupling element when coupling.

- Tilt control of rail vehicles.

Îä≥ÿœµΩy

Battery Systems

For filling and replacing battery fluid, Parker QCDE has developed a special coupling

system for the area of rail vehicles, which is used both in initial fitting and in maintenance.

- Extremely light due to material selection of aluminium.

- Special seals that withstand distilled water long-term.

- Quick coupling systems with dry-break locking system allows clean handling and protection

of the surroundings.

Product Solutions in the Area of Plumbing,Brakes and Other Pneumatic Applications

‘⁄ÑxÐáπЬ∑œµΩy∫Õ∆‰À˚ö‚є뙔√ÓI”ÚµƒÆa∆∑Ω‚õQ∑Ω∞∏

Product Solutions in the Area of Cooling, Battery Systems and Other Hydraulic Application

‘⁄¿‰Ös£¨Îä≥ÿœµΩy∫Õ∆‰À˚“∫â∫ë™”√ÓI”ÚµƒÆa∆∑Ω‚õQ∑Ω∞∏

»Á∫Œ¥_±����£°∞èÕ≈dÃñ°±∞≤»´”‰øϵƒþ\––�����£ø

ÐÎäπ≠ «◊Ó÷ÿ“™µƒ‘Olj÷Æ“ª

ÐÎäπ≠◊˜ûÈÎ䡶Ýø“˝¡–ÐáÐáðvèƒΩ””|æW»°µ√ÎäƒÐµƒÎäö‚‘Olj£¨∞≤—b‘⁄ÐáðvÌî≤ø���°£¡–ÐáÕ®þ^ ÐÎäπ≠ С˜����£¨å¢Îäâ∫èƒΩ””|æW“˝»Î¡–Ðá���£¨Ωõþ^Ωµâ∫���°¢’˚¡˜�°¢ƒÊ◊ɵ»¥Î ©�����£¨œÚ¡–Ðá‘Olj÷π©þm∫œµƒπ§◊˜Îä‘¥�����°£Õ®À◊ÅÌ÷v£¨ ÐÎäπ≠œýÆî”⁄°∞èÕ≈dÃñ°±µƒ≤ÂÓ^���£¨Õ®þ^À¸≈cÎäæWµƒΩ””|åç¨F’˚Ðá ÐÎä°£≈…øÀùhƒ·∑⁄’˝ «åç¨F’˚Ðá∆Ω∑Ä ÐÎä���°¢∞≤»´þ\––µƒÍPÊIπ©ë™…ð£

÷∆Ñ”œµΩy «∏þËFµƒ∫À–ƒÍPÊIœµΩy

◊Ó∆Ω≥£µƒ◊˜”√ «øÿ÷∆Ðáðv∞≤»´Õ£Ðá�£¨å¶ðd»À≥…«ß…œ∞Ÿµƒ∏þÀŸ¡–ÐáÅÌ’f��£¨÷∆Ñ”œµΩy◊ɵ√œýÆîèÕÎs°£≈…øÀùhƒ·∑⁄∏þ∆∑Ÿ|µƒÆa∆∑¥_±£÷∆Ñ”œµΩyÕÍ√¿þ\––����£¨ïrÀŸ400π´¿Ôµƒ°∞èÕ≈dÃñ°±ø…ú ¥_üo’`µƒÕ����£øø‘⁄÷∏∂®Œª÷√�£¨∏¸Ωo”Ë≥ÀøÕ¡º∫√µƒ Êþmµƒ≥ÀÐáÛwÚû����°£

¥_±£Ðáé˚É»ö‚â∫∑Ä∂®µƒÈTœµΩy≈cø’’{œµΩy

¡–Ðá∏þÀŸþ\––ïr£¨ø’ö‚ö‚â∫∂∏‘ˆ≤¢◊˜”√”⁄ÐáÛw£¨»Áπ˚”–ö‚¡˜Œ¥Ωõøÿ÷∆æÕþM»ÎÐáé˚É»����£¨å¢åß÷¬≥ÀøÕµƒ≤ª¡º∏– Ð�����£¨≈…øÀùhƒ·∑⁄µƒö‚Ñ”ÓêÆa∆∑ πµ√ÈTœµΩyƒÐæo√ПN∫œ”⁄ÐáÛw£¨±£◊C¡Àø’’{œµΩy∆Ω∑Äþ\––��£¨¥_±£¡ÀÐáé˚É»ö‚â∫µƒ∑Ä∂®�£¨Õ¨ïrÐáðvµ÷þ_’æ≈_∫Û”÷±£◊C¡ÀÐáÈT∞¥“é∂®ïrÈg°¢“é∂®µƒ¡¶æý¥ÚÈ_≈cÈ]∫œ����°£

¥ÀÕ‚≈…øÀùhƒ·∑⁄ûÈ°∞èÕ≈dÃñ°±π©ë™„^æ蜵Ωy“‘º∞ðo÷˙ö‚‘¥œµΩyµ»����°£

¿^°∞∫Õ÷CÃñ°±∫Û�£¨≈…øÀùhƒ·∑⁄≈c°∞èÕ≈dÃñ°±µƒ∫œ◊˜∏¸º”…Ó∂»æo√а£

- þ^”≤µƒºº–gå硶°¢º∞ïrÌëë™∑˛Ñ’ƒÐ¡¶£¨ πµ√≈…øÀùhƒ·∑⁄”–ƒÐ¡¶≈cøÕëÙπ≤Õ¨È_∞l�£¨Ã·π©∂®÷∆ªØÆa∆∑

- ºØ≥…∂ý∑Nπ¶ƒÐƒ£âK��£¨ûÈøÕëÙÃ·π©œµΩyªØΩ‚õQ∑Ω∞∏£¨∑Ω±„øÕëÙ∞≤—bæS–Þ

- Æa∆∑–π¬©þhµÕ”⁄––òIòÀú

- 60 Years of Know-How - We set standards industrywide

Brief insight into our range of services in the railway sectorÆa∆∑∑∂á˙

|

|

Rectus 303 SeriesøÏÀŸΩ”Ó^ |

|

|

|

|

|

|

|

|

|

|

|

Parker QD Series Straight through couplings

QDœµ¡–÷±Õ® ΩøÏÀŸΩ”Ó^ |

|

|

|

|

Rectus 26 Series Universal brass coupling

26œµ¡–øÏÀŸΩ”Ó^ |

|

|

Tema FF series double shut-off, dry-break and single-handed operation FFœµ¡–ÎpœÚÍPîý∆Ω√ÊøÏÀŸΩ”Ó^ |

|

|

|

|

Parker Snap-tite H series is a general purpose

hydraulic and pneumatic quick coupling. 1/4" up to 6" |

|

|

Parker Snap-tite 71 series couplings

71œµ¡–∆Ω√ÊøÏÀŸΩ”Ó^ |

|

Parker NSR Series Dry-Break coupling

Parker STR Series Straight-Through coupling

Parker NSA Series Dry-break poppet valve couplings

Parker QD Series Straight through couplings

QDœµ¡–÷±Õ® ΩøÏÀŸΩ”Ó^

Rectus 200KL Series Dry-break coupling

200KLœµ¡–≤ª–π¬∂øÏÀŸΩ”Ó^

Rectus 21 Series Mini industrial coupling

21œµ¡–√‘ƒ„–Õπ§òIøÏÀŸΩ”Ó^

Rectus 26 Series Universal brass coupling

Tema FF series double shut-off, dry-break and single-handed operation

Tema FEM series ISO Standard 16028

ÃÏÒRFEMœµ¡–øÏÀŸΩ”Ó^

Tema SK Series Screw-to-connect coupling

ÃÏÒRSKœµ¡–¬ðºyþBΩ”øÏÀŸΩ”Ó^

Parker Snap-tite H series is a general purpose

hydraulic and pneumatic quick coupling.

Parker Snap-tite 71 series couplings

Transportation - Railway

Parker Hannifin Manufacturing

Germany GmbH & Co. KG Quick Coupling Division Europe

Vibrations, dirt and extreme mechanical and climatic stress are the principal challenges for our quick connect coupling systems in the area of electric and diesel-powered rail vehicles. The functional safety of the systems plays a major role here with the many electronic, pneumatic and hydraulic controls, in addition to the requirements with respect to reliability (failure safety) and availability. Particularly in the area rail, there are specific directives and safety standards for processes, with which our systems must c comply (for example the vibration and shock test in accordance with DIN EN 61373/IEC 61373).

With over 60 years of experience in the development and sale of high-quality quick connect coupling systems, the Quick Coupling Division Europe of Parker Hannifin ®C the world°Øs leading manufacturer in motion and control technologies ®C now offers one of the most extensive product ranges of innovative connection solutions. Whether for complete or sub-systems, we always have a tried and tested solution.

From standard product to bespoke systems, our team is available to provide you with competent advice at any time. We are happy to provide detailed advice ®C please ask us.

Maximum Precision and Reliability - The product advantages at a glance:

- High resistance to vibrations and dirt (e.g. NSR-Series).

- Certified safety ®C vibration and shock test in accordance with DIN EN 61373/IEC 61373.

- Low pressure drop for maximum energy efficiency.

- Compact design for installation in applications where little space is available.

- Various sizes from nominal diameter 3 mm up to 50 mm.

- Broad selection of sealing materials for optimal co-ordination with temperature (-55°„C up to +250°„C) and flow medium.

- High resistance to rotation.

- No leakage when disconnected due to the specially developed valve design ®C even after a long time and pressurisation (all flat-sealing variants).

- Push-pull function ®C pull-off function for system safety and time saving, particularly with systems in motion (e.g. FF-Series).

|